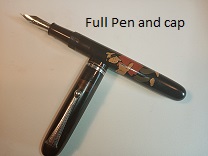

These pens have a seal to the barrel end and a piston rod in the barrel that is coned to fit the coned depression in the feed, shutting off and regulating ink supply to the feed. The seals in the barrel end are held in place usually by a hard rubber threaded closer washer.

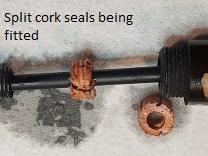

Not all pens are the same and have a variety of fittings to the seals. Generally, the pens seals, where it is thought, able to last the lifetime of the pens and not requiring servicing. As vintage pens become more desirable for use and collection, the failed seals on these pens need replaced, for this I prefer to use Viton “O” rings as opposed to the original cork, where possible. The seal is purely to stop ink leaking from the back end of the pen when the ink regulator piston rod and feed seal is implemented.

I will describe four types of method for the seal renewal, the third process and the one most invasive, to be avoided if possible. This will only be described as I do not have to hand an example of the process.

The fourth processes as the third is only described for the same reason as above.

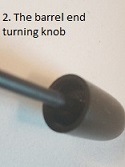

- Very occasionally the turning knob will unscrew from the piston rod allowing easy access to the closer washer. Shown here with piston removed from an ONOTO pen, who use a similar type of ink regulator with the piston rod cone. This is shown on ONOTO adverts and also their patents, it is debateable on ONOTO pens that the piston head seal, effects the seal against the end of the section threads?

- the photographs describe the most common method of barrel end seal replacement, cork split seal being used.

- Extremely rarely the whole barrel back end threaded section will unscrew from the barrel accessing internally a method of installing a seal.

- One scan shows a magnet detecting a steel core to the piston. Against the purists, at times, when none of the above methods can be detected for seal access and piston has to be removed for lathe work. In these cases, the piston rod must have as steel core. Below the lever of the cap turning button, the hard rubber outer cover is cut and the turning button with a section of the piston rod cover can be removed. On completion of replacement seal and cover, the turning button and part rod is re-united with the full rod, I use “Liquid Weld” to ensure as permanent as possible a solid solution

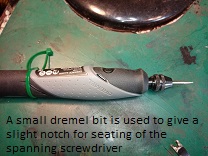

Very careful use of local heat is normally required here, I also heat the spanning screwdriver, to impress into the seal retaining collar

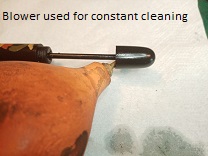

The seal has all now been accessed and old seal material cleared out during each operation all excess material should be cleared.

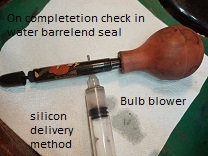

Most importantly after carrying out any pen works is to check your works. Prior to filling with ink to check, I use a blower again, this time one that fits and seals over the section, with the barrel end immersed in water, checking no air bubbles on depression of the bulb blower. As with sac’d pens the slightest pin prick of air ingress will cause ink to “flood” on writing. Very important on testing a pen after servicing, is to fill with ink for writing, not simply dip testing the nib.

Not totally necessary, but on fitting the section after filling a touch of Rosin based sealant, easily removed gives an extra level of sealing.

It should be noted that these pens many times have very expensive Urushi lacquered barrels and are premium priced. The heat and works required can easily result in irreparable damage!